- Home

- About Us

- Product

- Capacitor

- Air-Conditioner Parts

- Compressor

- Universal A/C Control System & Remote

- Temperature Controller

- Contactor & Transformer

- Relay & Overload & Delay Timer

- Indoor And Outdoor Air Conditioning Motor

- Defrost Timer

- Thermostat Guard

- Select Switch

- Fan Blade

- Air Conditioner Bracket

- A/C Flow Deflector & A/C Service Bag

- High Pressure Washer

- Charging Valve & Capillary & Wave Tube

- All A/C Brands Sensor

- Insulation tuber

- Refrigerator Parts

- Refrigeration Parts

- Axial Fan

- Microcomputer Temperature Control

- Voltage Protector

- Vacuum Pump & Refrigerant Recovery Unit & Scale

- Brass & Copper Fitting

- Installation Material

- PVC Air Curtain

- Condensate Drain Pump

- Refrigerant

- Copper Tube

- Filter Drier & Oil Separator For Refrigeration System

- Vibration Absorber

- Control Valve & Fitting & Component

- Manifold Gauge

- Thermometer

- Air Curtain

- Condenser Unit

- Condensing Unit

- AC Cooling Fan

- Refrigerant Leak Detector

- Latch & Hinge

- Washing Machine Parts

- Home Appliances Parts

- Instruments&Tools

- Resources

- News

- Contact Us

Web Menu

- Home

- About Us

- Product

- Capacitor

- Air-Conditioner Parts

- Compressor

- Universal A/C Control System & Remote

- Temperature Controller

- Contactor & Transformer

- Relay & Overload & Delay Timer

- Indoor And Outdoor Air Conditioning Motor

- Defrost Timer

- Thermostat Guard

- Select Switch

- Fan Blade

- Air Conditioner Bracket

- A/C Flow Deflector & A/C Service Bag

- High Pressure Washer

- Charging Valve & Capillary & Wave Tube

- All A/C Brands Sensor

- Insulation tuber

- Refrigerator Parts

- Refrigeration Parts

- Axial Fan

- Microcomputer Temperature Control

- Voltage Protector

- Vacuum Pump & Refrigerant Recovery Unit & Scale

- Brass & Copper Fitting

- Installation Material

- PVC Air Curtain

- Condensate Drain Pump

- Refrigerant

- Copper Tube

- Filter Drier & Oil Separator For Refrigeration System

- Vibration Absorber

- Control Valve & Fitting & Component

- Manifold Gauge

- Thermometer

- Air Curtain

- Condenser Unit

- Condensing Unit

- AC Cooling Fan

- Refrigerant Leak Detector

- Latch & Hinge

- Washing Machine Parts

- Home Appliances Parts

- Instruments&Tools

- Resources

- News

- Contact Us

Product Search

Exit Menu

Understanding Air Conditioner Magnetic Contactors: A Comprehensive Guide

Posted by Admin | 31 Jul

- 1 What Is an Air Conditioner Magnetic Contactor and How Does It Work?

- 2 Signs You Need to Replace Your AC Unit Contactor Switch

- 3 How to Choose the Right HVAC Magnetic Contactor Specifications

- 4 The Complete Process for Testing AC Contactor Relay Functionality

- 5 Understanding Contactor Wiring Diagram for AC Units

- 6 Preventive Maintenance for Air Conditioner Power Relay Components

What Is an Air Conditioner Magnetic Contactor and How Does It Work?

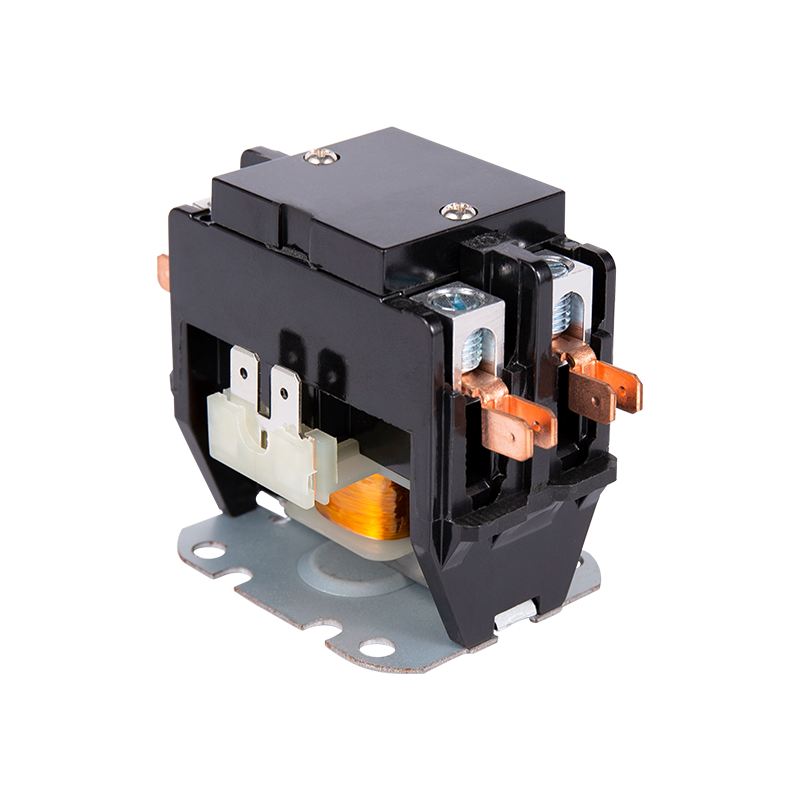

The air conditioner magnetic contactor is a crucial electromechanical switch that controls the flow of electricity to your AC unit's compressor and fan motor. These devices are designed to handle high-current loads that would be impractical for standard switches to manage directly.

Magnetic Contactor For Air Conditioner With 240V/AC

Basic Working Principle

When the thermostat calls for cooling, it sends a low-voltage signal to the contactor's coil. This creates a magnetic field that pulls the contacts together, completing the high-voltage circuit to the compressor and condenser fan. The process happens in milliseconds but is fundamental to your AC's operation.

Key Components

- Electromagnetic coil (creates the magnetic field when energized)

- Stationary contacts (fixed part of the switching mechanism)

- Moving contacts (connected to the armature that moves when coil is energized)

- Enclosure (protects the components from environmental factors)

- Arc chute (helps extinguish sparks when contacts open)

Why Magnetic Contactors Are Essential

Unlike manual switches, magnetic contactors provide several advantages for air conditioning systems:

- They allow low-voltage control of high-power circuits

- They provide safe electrical isolation when the system is off

- They can handle frequent switching cycles without degradation

- They offer overload protection capabilities

Signs You Need to Replace Your AC Unit Contactor Switch

The AC unit contactor switch is a wear item that eventually needs replacement. Recognizing the symptoms of a failing contactor can prevent more serious system damage.

Common Failure Symptoms

- AC unit not turning on despite thermostat settings

- Intermittent cooling where the system turns on and off randomly

- Visible pitting or burning on the contact surfaces

- Audible buzzing or chattering noises from the contactor

- System works but draws excessive current (measured by an amp meter)

Lifespan Expectations

While contactor lifespan varies, here's a comparison of typical durability under different conditions:

| Operating Condition | Expected Lifespan |

|---|---|

| Normal residential use (3-6 months/year) | 10-15 years |

| Heavy residential/commercial use | 5-8 years |

| High humidity/salt air environments | 3-5 years |

| Areas with frequent power surges | 2-4 years |

Diagnostic Checks

Before replacing the contactor, perform these verification steps:

- Check for 24VAC at the contactor coil terminals when thermostat calls for cooling

- Inspect contacts for carbon buildup or physical damage

- Test continuity across closed contacts (should be near zero resistance)

- Measure voltage drop across contacts when energized (should be minimal)

How to Choose the Right HVAC Magnetic Contactor Specifications

Selecting appropriate HVAC magnetic contactor specifications ensures reliable operation and prevents premature failure. Several technical factors must be considered.

Voltage Ratings

The contactor must match your system's voltage requirements:

- Coil voltage (typically 24VAC for residential HVAC)

- Main contact voltage rating (usually 240VAC or higher)

- Control circuit isolation voltage

Current Capacity

Current ratings are perhaps the most critical specification. The table below shows typical requirements:

| AC Unit Tonnage | Minimum Contactor Rating | Recommended Rating |

|---|---|---|

| 1.5 Ton | 30A | 40A |

| 2 Ton | 40A | 50A |

| 3 Ton | 50A | 60A |

| 4 Ton | 60A | 70A |

| 5 Ton | 70A | 90A |

Pole Configuration

HVAC contactors come in different pole configurations:

- Single pole (controls just the compressor)

- Double pole (controls compressor and fan simultaneously)

- Three pole (for specialized commercial applications)

The Complete Process for Testing AC Contactor Relay Functionality

Properly testing AC contactor relay components can save time and money by accurately diagnosing problems. Follow this systematic approach.

Safety Precautions

Before testing:

- Turn off power at the breaker and verify it's dead

- Discharge capacitors if present

- Use insulated tools

- Wear personal protective equipment

Step-by-Step Testing Procedure

- Visual inspection for burnt marks, melted plastic, or corroded terminals

- Check coil resistance with a multimeter (typically 10-100 ohms)

- Verify coil voltage when thermostat is calling

- Test contact resistance when engaged (should be <1 ohm)

- Measure voltage drop across closed contacts (<1VAC)

- Check for proper contact alignment and full engagement

Interpreting Test Results

Understanding what your measurements indicate:

| Measurement | Good Reading | Problem Reading |

|---|---|---|

| Coil Resistance | Within 10% of rated value | Open circuit or significantly higher |

| Contact Resistance | <1 ohm | >5 ohms |

| Voltage Drop | <1VAC | >2VAC |

| Pickup Voltage | 80% of rated voltage | Requires >90% of rating |

Understanding Contactor Wiring Diagram for AC Units

The contactor wiring diagram for AC units provides the roadmap for proper installation and troubleshooting. While models vary, most follow similar basic principles.

Standard Terminal Identification

Most HVAC contactors use these terminal markings:

- L1/L2/T1/T2 - Main power contacts

- A1/A2 - Coil connections

- 13/14 - Auxiliary contacts (if present)

Residential AC Wiring Schematic

A typical wiring configuration includes:

- 240VAC supply connected to L1 and L2

- Compressor leads connected to T1 and T2

- 24VAC control circuit connected to A1 and A2

- Potential relay or start capacitor wiring if applicable

Common Wiring Mistakes

Installation errors to avoid:

| Mistake | Consequence | Correction |

|---|---|---|

| Undersized wires | Overheating, voltage drop | Use proper gauge per NEC |

| Loose connections | Arcing, contact damage | Proper torque on terminals |

| Wrong coil voltage | Failure to operate or coil burnout | Verify system control voltage |

| Missing jumpers | Single phasing on 3-phase | Follow diagram exactly |

Preventive Maintenance for Air Conditioner Power Relay Components

Regular care of air conditioner power relay components extends equipment life and prevents unexpected failures. These practices apply to both homeowners and technicians.

Scheduled Maintenance Tasks

A comprehensive maintenance routine should include:

- Annual inspection of contact surfaces

- Checking and tightening all electrical connections

- Verifying proper coil voltage during operation

- Testing contact resistance periodically

- Cleaning dust and debris from the contactor area

Contact Maintenance Techniques

Proper contact care involves:

- De-energizing the system completely

- Inspecting for pitting or oxidation

- Lightly cleaning with contact cleaner if needed

- Never filing contacts unless absolutely necessary

- Checking contact alignment after maintenance

Environmental Protection

Protecting contactors from harsh conditions:

| Environmental Factor | Protection Method | Maintenance Frequency |

|---|---|---|

| Moisture | Weatherproof enclosure | Seasonal check |

| Dust/Debris | Proper sealing | Annual cleaning |

| Corrosive Air | Corrosion-resistant materials | Bi-annual inspection |

| Vibration | Anti-vibration mounts | During service calls |

Efficient charging, stable output, capacitor, thefirst choice for electric drive.

- Address: North of Funing Rd., Helixi Economic and Technology Development Zone, Ningguo, Anhui, China

- Phone/WhatsApp: +86-18110862602

- Email: [email protected]

If you have anything to consult, you canfollow us, we will contact you as soon aspossible

Copyright © Ningguo Kingcool Import and Export Co., Ltd All Rights Reserved. Custom HVAC Parts & Accessories Suppliers