Does the Washing Machine Universal W/M Control System support data integration with these advanced production equipment to achieve real-time monitoring and precise control of the production process, thereby improving production efficiency and product quality?

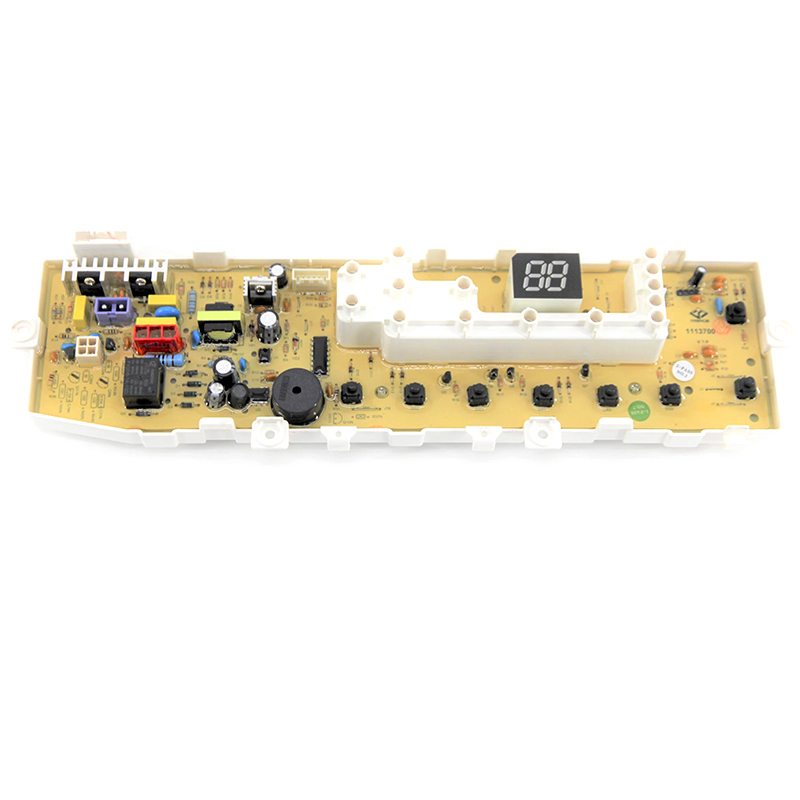

Washing Machine Universal W/M Control System is a control system specially designed for the production management of washing machines and accessories. It plays a crucial role in supporting data integration with advanced production equipment and realizing real-time monitoring and precise control of the production process. important role, thereby significantly improving production efficiency and product quality.

1. Data integration capabilities

Universal W/M Control System has powerful data integration capabilities and can easily and seamlessly connect with various advanced production equipment. Through standardized data interfaces and communication protocols, the system can collect data information in real time from high-precision slitting and winding equipment, sensors on the production line, quality inspection equipment, etc. These data include but are not limited to production progress, equipment status, material consumption, product quality parameters, etc. Through data integration and integration, the system provides comprehensive and accurate information support for production management.

2. Real-time monitoring and precise control

Based on data integration, Universal W/M Control System realizes real-time monitoring of the production process. Through an intuitive graphical interface, production managers can view the running status of the production line, the working status of the equipment, and product quality data in real time. This real-time monitoring function helps to promptly detect problems and anomalies in the production process, so that quick and effective measures can be taken to correct them.

Universal W/M Control System also has the capability of precise control. Through the analysis and processing of production data, the system can automatically adjust production parameters, such as equipment operating speed, material input volume, temperature, etc., to ensure the stability and consistency of the production process. This precise control not only improves production efficiency, but also significantly reduces the scrap rate and defective rate, thereby improving product quality.

3. Improve production efficiency and product quality

Universal W/M Control System achieves comprehensive optimization of the production process through data integration, real-time monitoring and precise control. On the one hand, the system can automatically schedule and optimize production resources, such as equipment, personnel, materials, etc., to improve production efficiency and resource utilization. On the other hand, through in-depth mining and analysis of production data, the system can discover potential problems and improvement points in the production process, providing strong support for continuous improvement and optimization.

In terms of product quality, the system ensures the stability and consistency of the production process through real-time monitoring and precise control. At the same time, the system can also perform statistical analysis on product quality data, promptly discover quality problems and trace their root causes, so as to take targeted measures for improvement. This comprehensive monitoring and management of product quality helps improve the overall quality and market competitiveness of products.

Washing Machine Universal W/M Control System significantly improves production efficiency and product quality by supporting data integration with advanced production equipment and achieving real-time monitoring and precise control of the production process. The system provides comprehensive and accurate information support for the production management of washing machines and accessories, laying a solid foundation for the sustainable development of the enterprise.