How do Ningguo Kingcool's high-precision slitting and winding equipment and advanced production lines ensure the precision and consistency of the manufacturing process of the washing machine drain motor, thereby providing high-quality products?

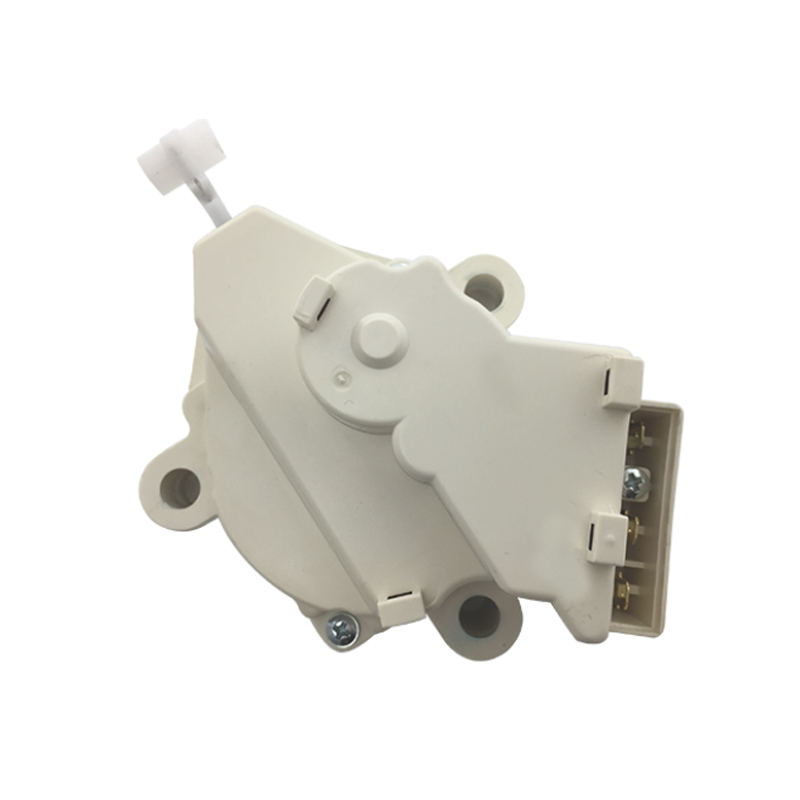

As a leading supplier of customized washing machine parts and accessories in China, Ningguo Kingcool Import and Export Co., Ltd.'s high-precision slitting and winding equipment and advanced production lines play a vital role in ensuring the precision and consistency of the manufacturing process of the Drain Motor For Washing Machine.

1. High-precision slitting and winding equipment: laying the foundation for manufacturing

Ningguo Kingcool's high-precision slitting and winding equipment is one of the key equipment in the manufacturing process of the washing machine drain motor. These equipment use advanced control technology to achieve precise slitting and winding of raw materials.

Precise slitting: High-precision slitting equipment can accurately slit raw materials according to preset sizes and shapes. This precise slitting capability ensures the consistency of the size and shape of the materials required in the manufacturing process of the drain motor, thereby improving the precision of the product.

Stable winding: The winding equipment is responsible for winding the slit materials into specific shapes and sizes. By precisely controlling the tension, speed and position of the winding, Ningguo Kingcool is able to ensure that the wound material has a high degree of stability and consistency, laying a solid foundation for the subsequent manufacturing process.

2. Advanced production line: achieving efficient manufacturing and quality control

On the basis of having high-precision slitting and winding equipment, Ningguo Kingcool is also equipped with advanced production lines that integrate a variety of advanced manufacturing technologies and equipment, such as automated assembly, precision machining and online testing.

Automated assembly: By adopting advanced automated assembly technology, Ningguo Kingcool is able to achieve precise assembly of various components of the drain motor. This automation technology not only improves assembly efficiency, but also ensures accuracy and consistency during the assembly process, thereby improving the overall quality of the product.

Precision machining: In the manufacturing process of the drain motor, many precise machining steps are involved, such as the installation of bearings, the winding of coils, etc. Ningguo Kingcool uses advanced precision machining technology and equipment to ensure the accuracy and consistency of these machining steps, thereby improving the performance and reliability of the Drain Motor For Washing Machine.

Online detection: In order to ensure the quality of the Drain Motor For Washing Machine, Ningguo Kingcool is equipped with advanced online detection equipment on the production line. These devices can monitor and detect various performance indicators of the drain motor in real time, such as speed, torque, noise, etc. By promptly discovering and correcting problems in the manufacturing process, Ningguo Kingcool can ensure that each drain motor meets high quality standards.

3. Comprehensive quality management: ensuring product consistency

In addition to high-precision slitting and winding equipment and advanced production lines, Ningguo Kingcool has also implemented comprehensive quality management measures to ensure the consistency and high quality of the drain motor for washing machines.

Raw material control: Ningguo Kingcool has strict control over the procurement and inspection of raw materials to ensure that the raw materials used meet high quality standards.

Process control: During the production process, Ningguo Kingcool uses advanced process control technology to monitor and control each link in the manufacturing process in real time to ensure product accuracy and consistency.

Finished product inspection: After the Drain Motor For Washing Machine is manufactured, Ningguo Kingcool will also conduct strict finished product inspections. These inspections include performance testing, appearance inspections and other aspects to ensure that each drain motor meets high quality standards.

Ningguo Kingcool ensures the accuracy and consistency of the Drain Motor For Washing Machine manufacturing process through high-precision slitting and winding equipment, advanced production lines, and comprehensive quality management measures, thereby providing high-quality products.