What is the difference between relays and contactors, and what are their respective application scenarios?

Both relays and contactors are commonly used switching elements in electrical equipment, but they have some important differences in function, structure and application scenarios. The following are the main differences between them and their respective application scenarios:

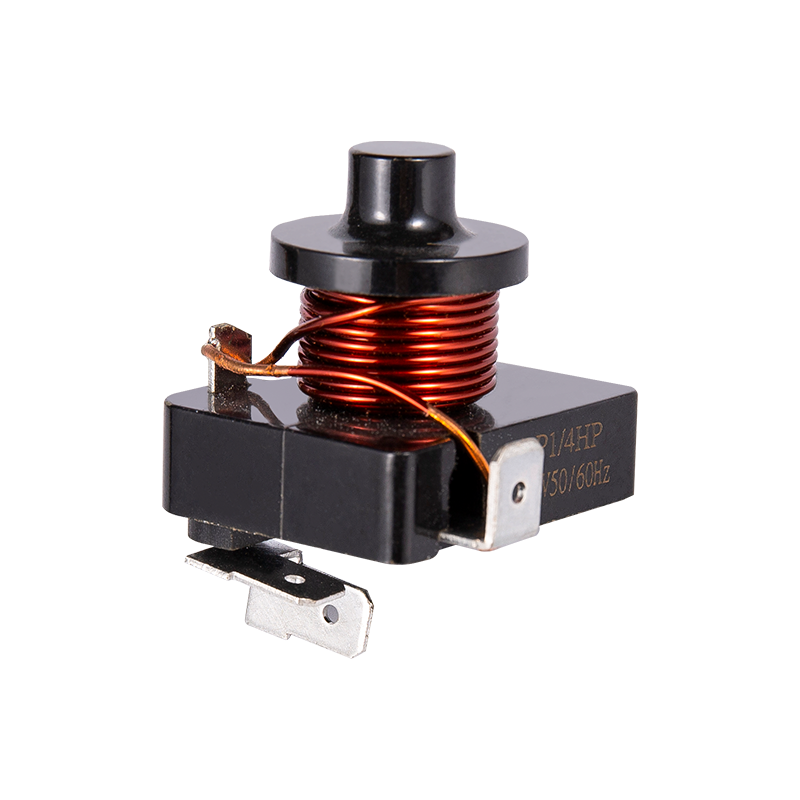

Relay

Definition and function:

Relay is an electromagnetic switch that can control the on and off of high-current circuits through electrical signals.

Mainly used for the control and protection of low-power equipment.

Features:

Fewer contacts: usually used to control a single circuit.

Fast response speed: suitable for frequent switching operations.

Small applicable current and voltage: generally used for low-power applications (such as signal control, automation equipment, etc.).

Application scenarios:

Automation control: such as output modules in PLC (programmable logic controller).

Signal control: in measuring equipment, sensors and alarm systems.

Household appliances: such as lighting control, timer switches, etc.

Contactor

Definition and function:

Contactor is an electromagnetic switch used to control electrical loads, mainly used for the control of high-power circuits.

Usually has a larger rated current and voltage.

Features:

More contacts: can control multiple circuits at the same time.

High durability: designed for frequent switching operations, suitable for high load and high current environments.

Equipped with auxiliary contacts: can achieve more functions, such as the linkage of indicator lights or relays.

Application scenarios:

Motor control: used for start and stop control of motors, such as water pumps, fans, etc.

Lighting control: in industrial lighting systems, used to control high-power lamps.

Power distribution system: used in distribution boards and industrial control cabinets.

Summary

Main differences:

Power and current: relays are used for low-power control, and contactors are used for high-power control.

Contact configuration: relays have fewer contacts, while contactors can control multiple loads.

Use scenarios: relays are mostly used for signal control, and contactors are mostly used for power control.

Selection suggestions: When choosing to use relays or contactors, you need to decide based on specific application requirements, load types, and control requirements.