What are the structural characteristics of bellows and how are they used to measure pressure or temperature?

Bellows are a commonly used pressure and temperature measuring device. Their structural characteristics and working principles make them widely used in many industrial fields. The following is a detailed introduction to the structural characteristics of bellows and how they are used to measure pressure or temperature:

Structural characteristics

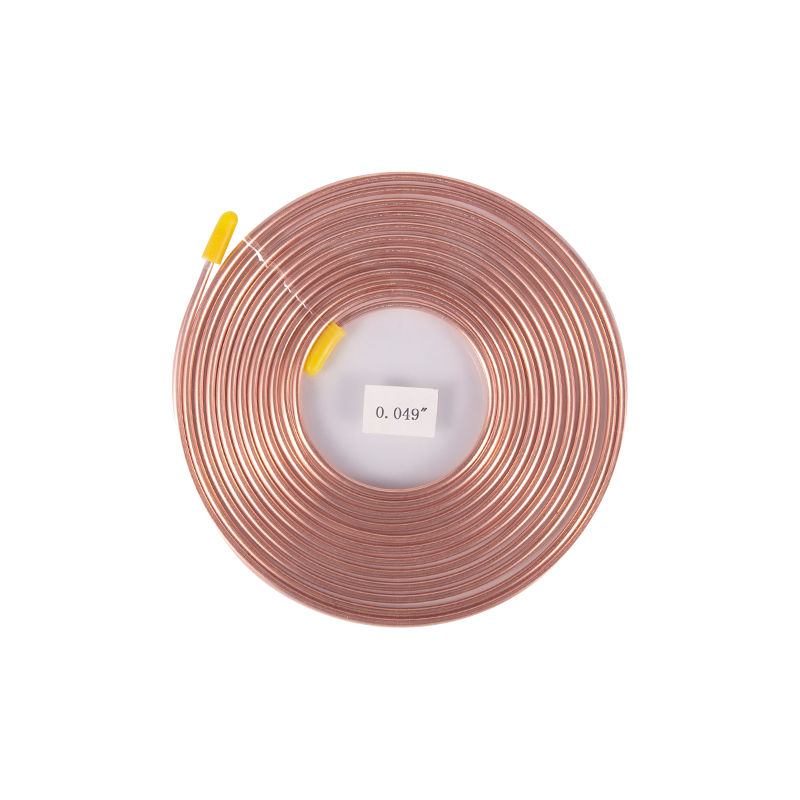

Corrugated structure: The bellows is made of a section of metal pipe with multiple corrugations on the pipe wall. This corrugated design allows the bellows to deform when subjected to external pressure or temperature changes.

Material: Bellows are usually made of materials such as stainless steel, copper or alloys, which have good mechanical strength and corrosion resistance.

Closed and open ends: One end of the bellows is usually open for contact with the measuring medium, while the other end may be closed or connected to the sensor.

Diameter and length: The diameter and length of the bellows can be customized according to application requirements to meet different measurement ranges and accuracy requirements.

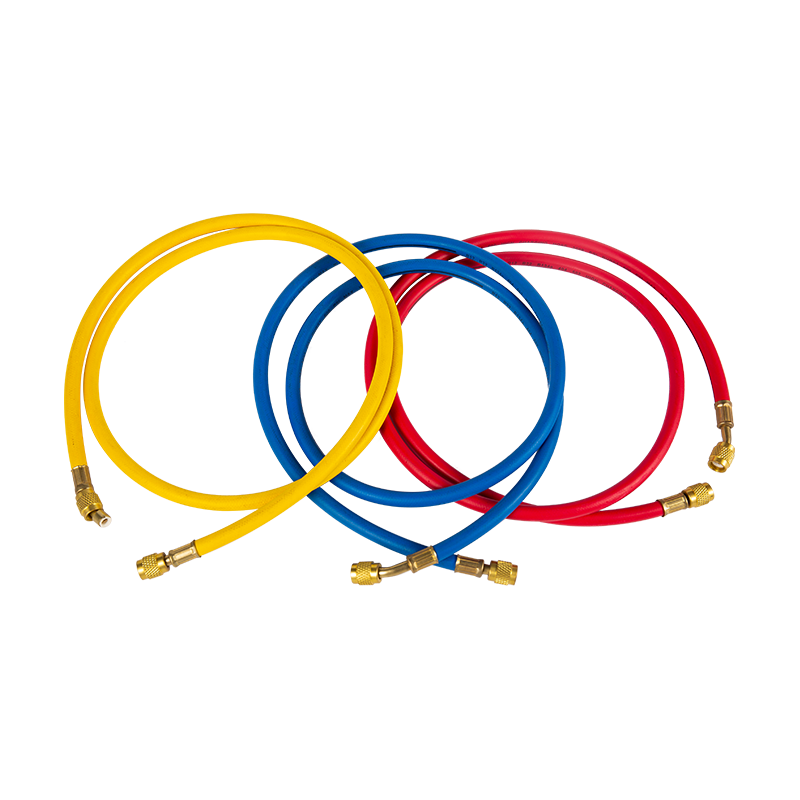

Connection interface: The design of the bellows is usually equipped with a standardized connection interface for easy connection with other instruments or equipment.

Measuring principle

Pressure measurement:

When one end of the bellows is exposed to the pressure to be measured, the pressure acts on the inner wall of the bellows, causing the bellows to deform.

The degree of deformation is proportional to the applied pressure. By measuring the deformation of the bellows, the applied pressure can be inferred.

This deformation is usually converted and displayed by a mechanical sensor (such as a pointer pressure gauge) or an electronic sensor (such as a pressure transmitter).

Temperature measurement:

Bells can also be used for temperature measurement, especially in high temperature environments. The principle is based on the property that temperature changes cause material expansion.

When the temperature of the medium in the bellows increases, the gas or liquid inside the bellows will expand, causing the bellows to deform.

By measuring the deformation of the bellows, the corresponding temperature change can be inferred. Similar to pressure measurement, this deformation can be converted and displayed mechanically or electronically.

Application areas

Industrial automation: widely used in pressure and temperature monitoring systems in factories.

HVAC systems: used for temperature and pressure measurement in refrigeration and air conditioning equipment.

Petroleum and Chemical Industry: Used to monitor pressure and temperature changes in chemical process control.